What software and methods do I use?

Finite Elemente Analysis (FEA)

![]()

is one of the largest providers of FEA software for simulations.

I have known and worked with Ansys for over 30 years. During this time, I have worked intensively on customising the software to make simulation processes more efficient.

![]()

is responsible for sales and support of Ansys in German-speaking countries. CADFEM provides me with excellent support and training whenever I have questions.

- Ansys Mechanical

Linear and non-linear mechanical simulations - Ansys Discovery

Fast rough optimisations

Execution of analytical calculations

eAssistant (the engineering Assistant) is a web-based calculation software developed by GWJ Technology GmbH from Braunschweig. It is used for the fast and convenient calculation, recalculation and optimisation of machine elements such as shafts, bearings, gears, springs, shaft-hub-connections, etc. according to calculation standards such as DIN / ISO and recognized technical literature.

Even if it sometimes makes sense to program a calculation specifically for your own company, it is cheaper and easier to use commercial products for standard calculations.

The design of gearboxes according to common standards such as ISO6336 is very complex and requires support.

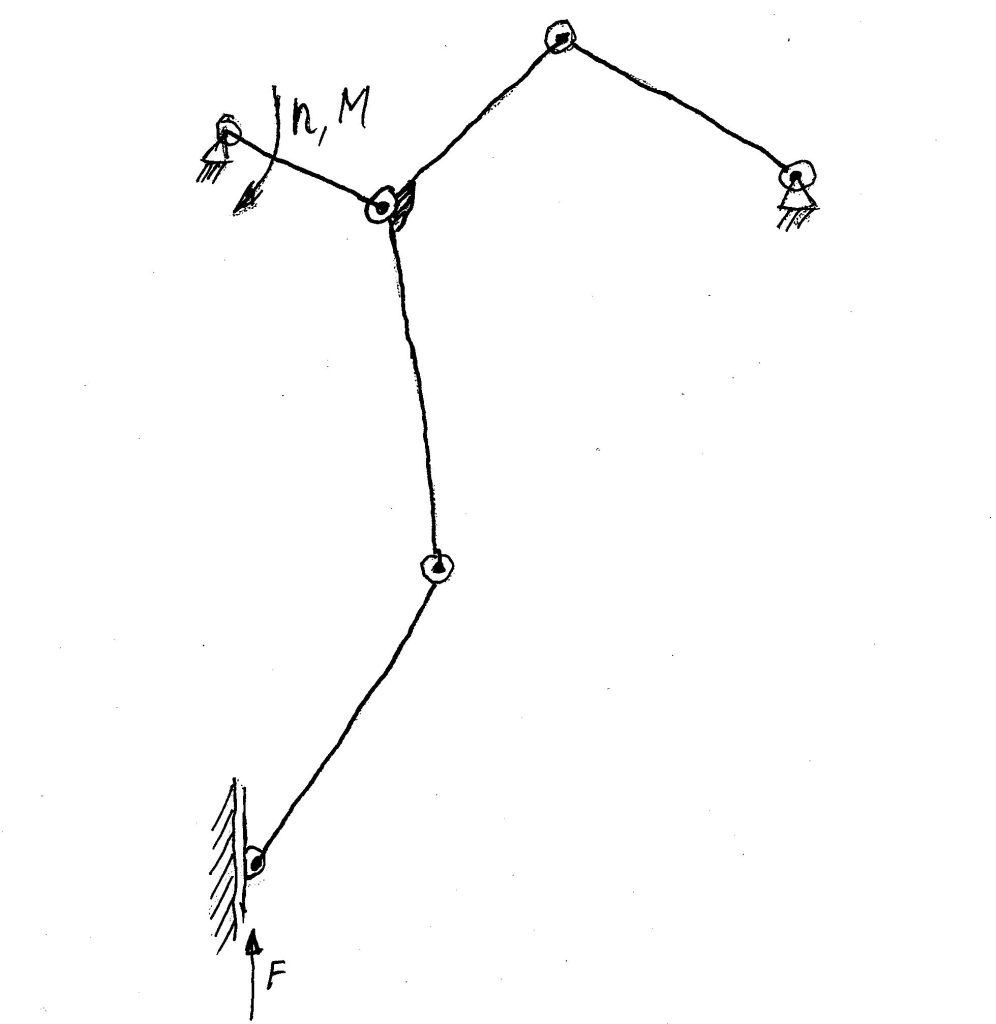

I use the following software for the multi-body simulation:

SAM

For simple plane problems with rigid bodies

ANSYS

For complex 3-d problems, also with elastic bodies

Control engineering simulations

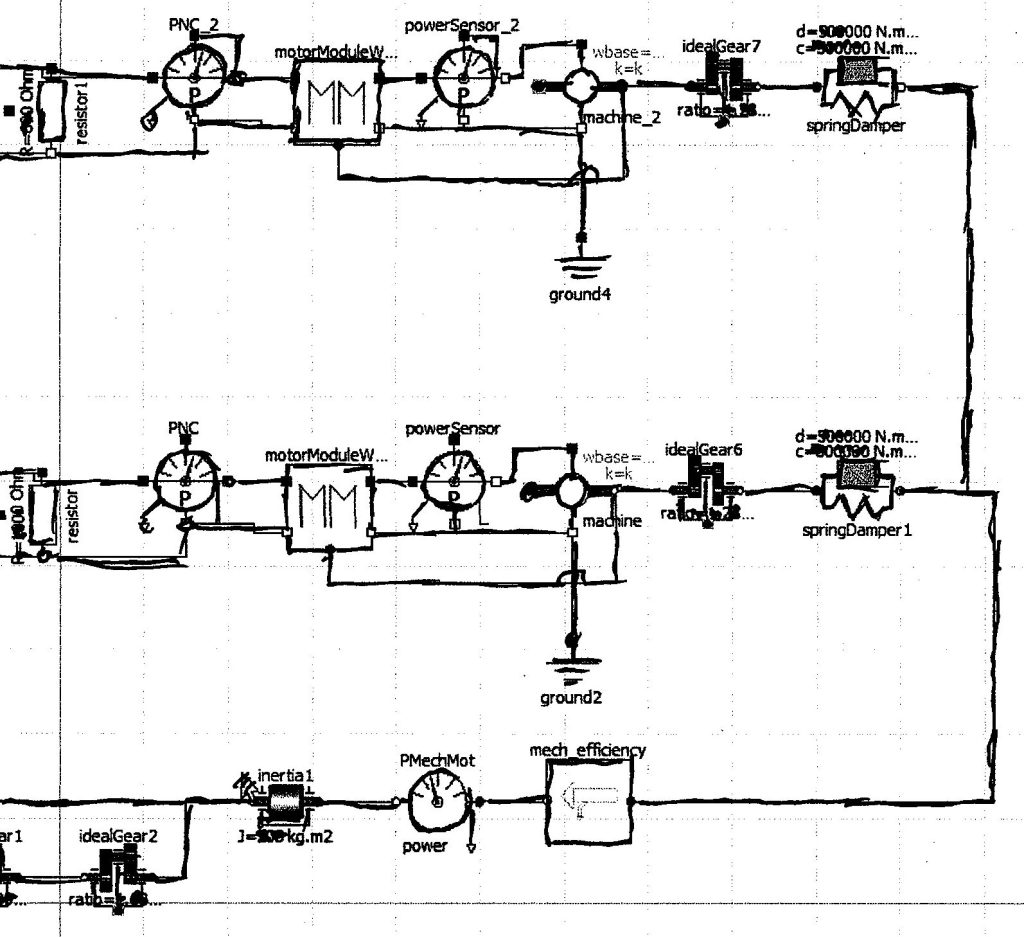

Modelica is an object-orientated open source modeling language for simulation, optimization and analysis of complex dynamic physical systems. It is also used in commercial software, e.g. Dymola, Dassault Systems...

OpenModelica is the appropriate modeling environment - also open source.

For example, OpenModelica can be used to dynamically simulate a complete drive train from the electrical grid, inverter, controller, electric motor, gearbox, lever gearbox to the load or torque introduction.

Programming of tools and linking programs

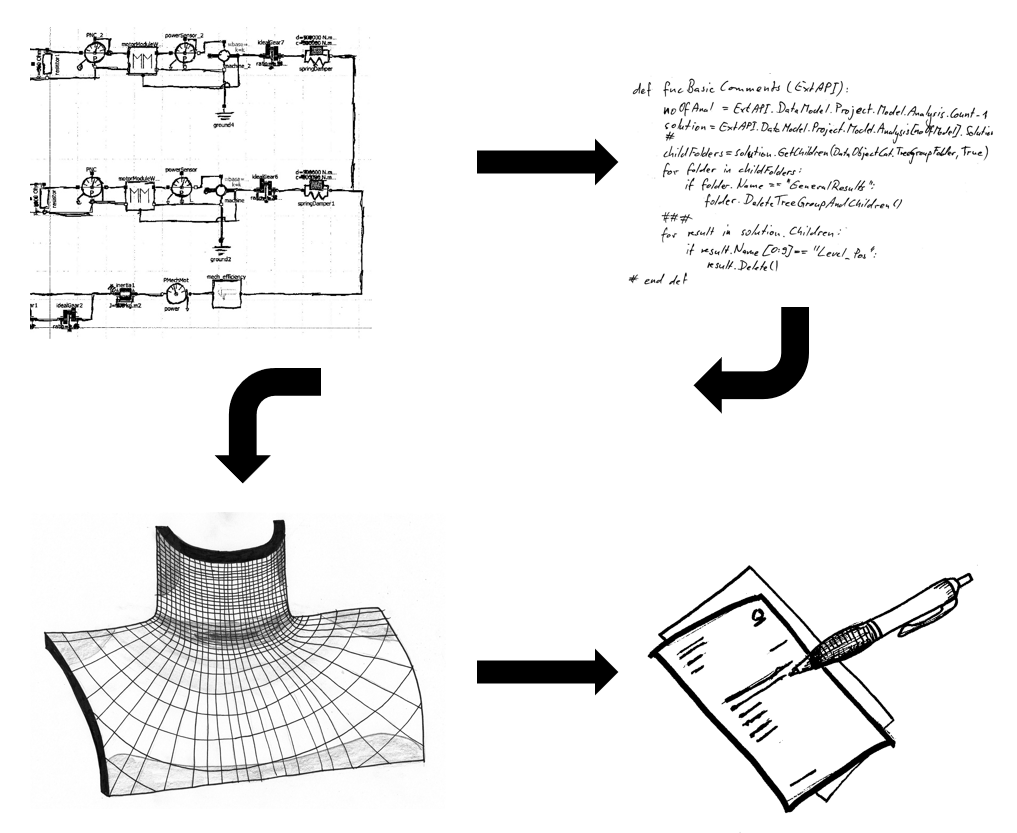

Depending on the task, it may make sense to combine different simulation methods. For example, the loads of an FEM calculation may come from a MBS, gearing calculation or control engineering simulation.

For regularly repeating simulations, it is recommended to automate the process. This reduces the risk of errors, especially with multiple users, and increases efficiency.

For this I use the programming languages Excel VBA, Phyten, VB.Net or C# as required.