Das Portfolio:

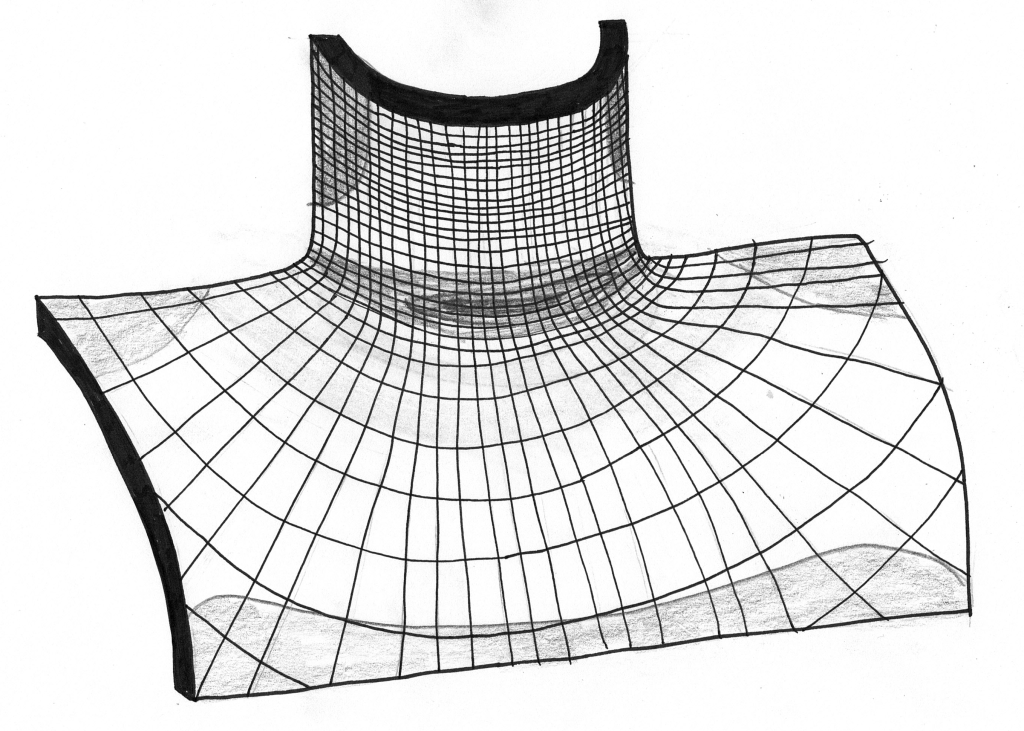

A huge range of different simulations can be carried out with FEM. However, it should not be forgotten that the results, these beautiful colourful images, must also be evaluated. This is often more difficult than the actual simulation.

I offer detailed consulting right from the start.

I offer the following analyses:

- Linear and non-linear static

- Assemblies with contacts

- Elastic-plastic material behaviour of steel and cast iron

- Thermal

- Vibrations

- Assessment of welded parts according to IIW guideline

- Assessment of components according to FKM guideline

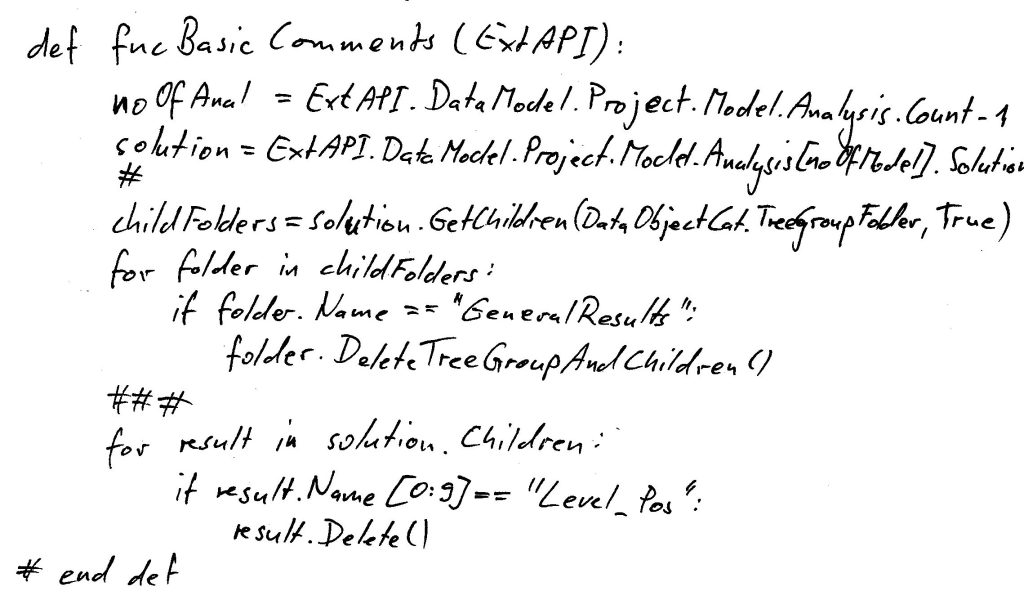

- Automation of repetitive calculations by programming workflows

- Development of calculation concepts for components / assemblies

If required, I am also willing to introduce myself to new topics.

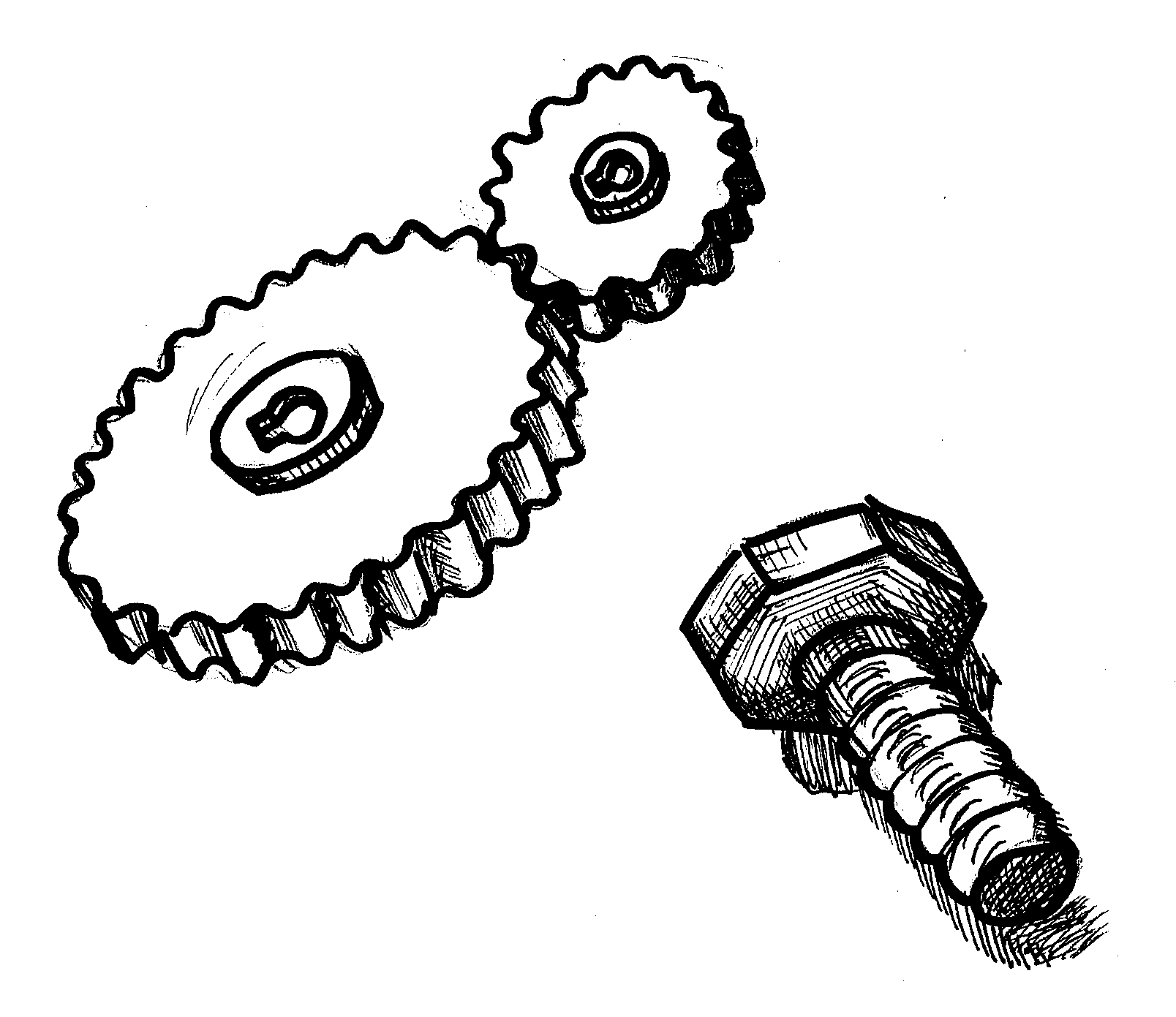

Execution of analytical calculations

In order to completely design a product, an assembly or a component, the interfaces must also be calculated. These are often standardised machine elements that must be correctly dimensioned.

In addition, these components often act as loads for other components.

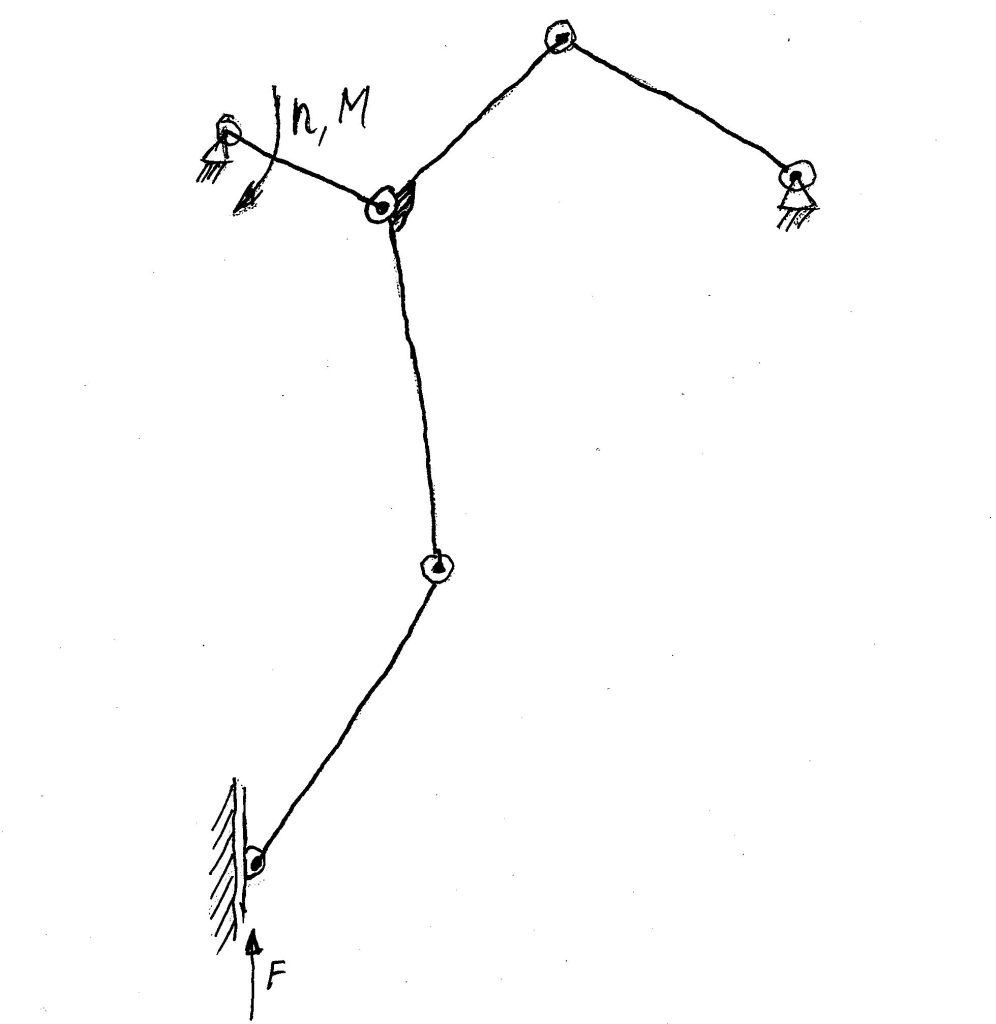

Multi-body simulation is about the analysis of (lever) gears. In the simplest case, these are assumed to be rigid and idealised using masses, mass inertias, joints, drives and boundary conditions.

Alternatively, elastic bodies can be used for simulation and optimization.

The following targets can be pursued, among others:

- Collision detection

- Calculation of forces, torques, power

- Calculation of velocities, accelerations, linear and rotational

- Kinematic motion design according to laws of motion (VDI 2143)

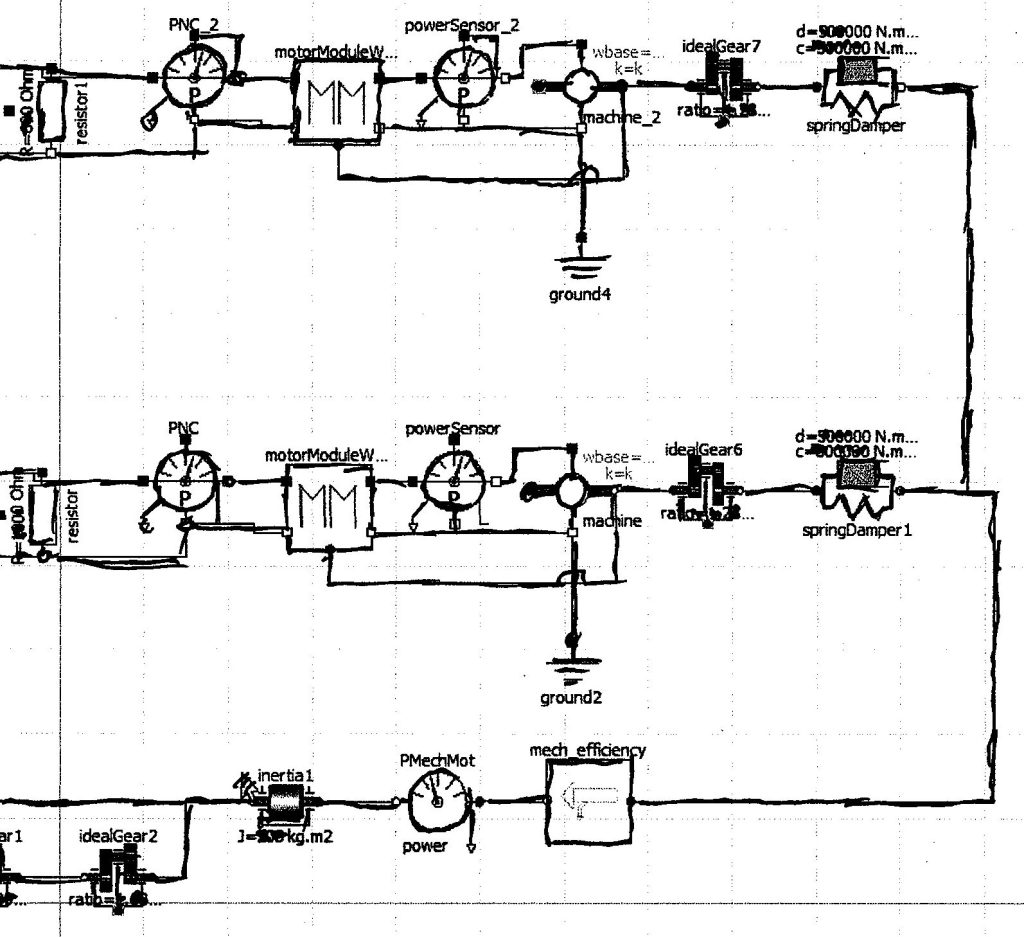

Control engineering simulations

Control engineering simulations are used to analyse and optimize complex dynamic physical systems.

For example, a complete drive train can be dynamically modeled, from the electrical grid to the inverter, controller, electric motor, gear drive, lever gear and load or torque introduction.

However, these are very complex tasks that require particularly close cooperation with the relevant specialized disciplines.

Developing analytical calculations

Sometimes it can be useful to program a calculation specifically for your own company. For example, if several calculations are to be linked, such as the design of a gear pair with the shaft hub connections and shaft deflections.

With such a company-specific calculation, all designers use the same coefficients and algorithms. In addition, the calculation time is shortened so that several alternatives can be calculated quickly. This software can be managed centrally with versioning and updates.

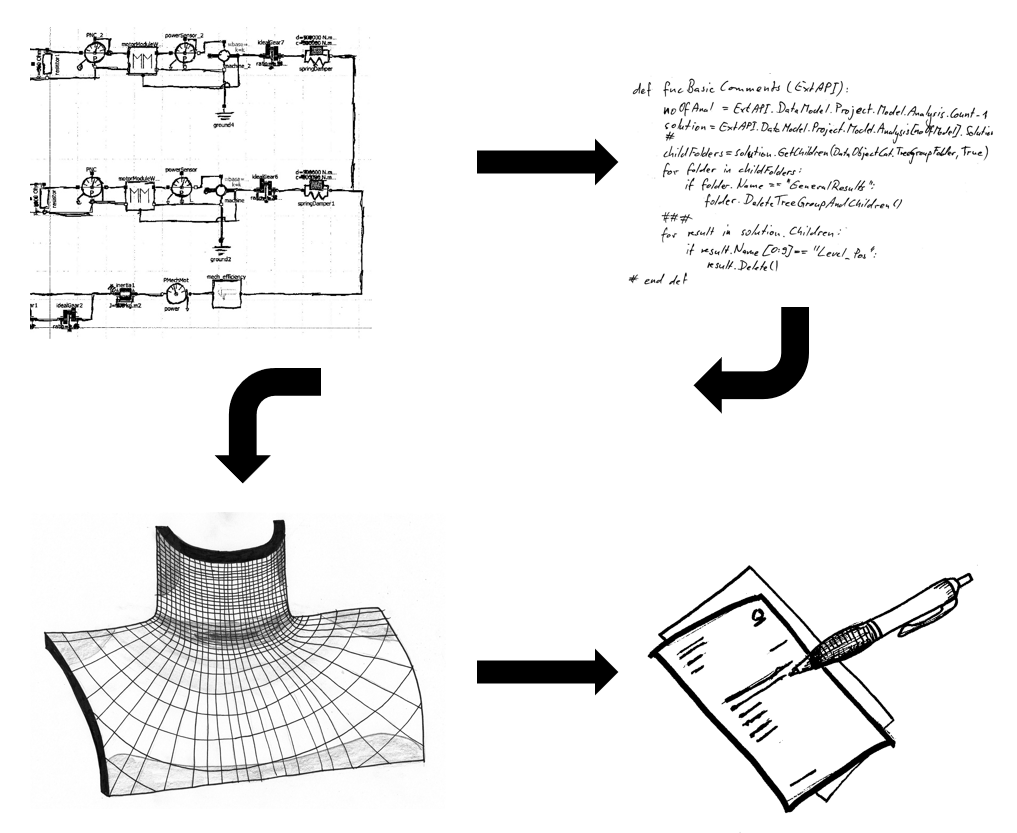

Linking different types of simulations

By combining different methods, an efficient and fast simulation can be achieved. Often it is necessary to create input data for the FEA, for example loads, through analytical calculations or control engineering simulations. If similar simulations are to be carried out regularly, the different methods can be combined.

This results in the following advantages:

- Reduction in simulation time

- Increase the number of variants => Faster and better optimisations

- Standardised procedures for simulations and reduction of possible errors

- The customer can run complex simulations themselves if necessary